Power quality refers to the stability and reliability of electrical power within a system, crucial for the efficient operation of devices and machinery. Poor power quality can cause issues such as voltage fluctuations, harmonic distortions, and electromagnetic interference, potentially damaging equipment and driving up energy costs. Ensuring good power quality is particularly vital for industries dependent on sensitive electronic devices, like healthcare, manufacturing, and data centers.

Inductors are passive components that play a crucial role in power quality by stabilizing current flow in a circuit. They store energy in a magnetic field when electrical current passes through, helping to filter out high-frequency noise and reduce harmonic distortions—common causes of poor power quality. By smoothing out current variations, inductors help prevent voltage sags and surges, ensuring a consistent power supply to connected devices. This makes them indispensable components in enhancing overall power quality.

Inductors play a crucial role in minimizing electromagnetic interference (EMI), which can disrupt the functionality of electronic devices and impair power quality. These components are essential in filtering out unwanted high-frequency signals. Integrated into EMI filters, inductors protect sensitive equipment from external interference, such as that originating from nearby electrical devices or power lines. By effectively suppressing EMIs, properly designed inductors not only ensure compliance with regulatory standards but also enhance the reliability of power systems overall. Such measures are vital for maintaining optimal power continuity and performance in various applications.

Harmonic mitigation is another critical application of inductors, as harmonics are unwanted frequencies that can distort the electrical power waveform and cause inefficiencies. Inductors are particularly effective in this regard when used in passive harmonic filters. These filters work by blocking or diminishing these disruptive frequencies. In industrial environments that operate non-linear loads such as variable frequency drives and rectifiers, inductors serve as an essential tool for maintaining power quality. By mitigating harmonics, they prevent potential equipment damage and optimize the efficiency of power systems, thereby ensuring that electrical operations remain smooth and consistent.

Selecting the right type of inductor is crucial for optimizing power quality. Air core inductors, which lack a magnetic core, are optimal for high-frequency applications as they minimize core losses and prevent saturation. They are especially useful in applications where low inductance values and reduced losses are paramount. Conversely, magnetic core inductors offer higher inductance values, making them ideal for low-frequency applications and enhancing power quality. These inductors are frequently used in environments where maintaining consistent inductance is essential. The decision between using an air core or magnetic core inductor hinges on factors such as frequency range and the specific power needs of the system.

High current inductors play a critical role in managing large electrical currents without compromising efficiency. Their design incorporates several key elements to ensure durability and functionality. First, choosing low-resistance materials for construction is essential to maintaining efficiency. Second, thermal management strategies, such as using heat sinks or forced air cooling, are crucial for preventing overheating. Lastly, these inductors need robust construction to withstand the demanding conditions they face in power supplies, renewable energy systems, and industrial machinery. By addressing these factors, high current inductors can maintain reliability and efficiency, even under substantial current loads.

Selecting the appropriate inductor for your power system is crucial to optimize performance. The key factors to consider include the inductance value, current rating, frequency range, and core material, each of which plays a pivotal role in ensuring compatibility with your system. For high-frequency noise applications, air core inductors might be preferable, as they prevent saturation and core losses. Conversely, magnetic core inductors are more effective for mitigating low-frequency harmonics. Consulting with an expert or delving into manufacturer specifications can assist in selecting the optimal inductor tailored to your needs.

Integrating inductors into power circuits requires careful planning for optimal outcomes. Their positioning is vital; place them near the noise source or harmonics within the circuit to significantly reduce adverse effects on adjacent components. Routine maintenance and monitoring are equally important, as they allow for the early detection of issues and prevent failure, ensuring the long-term reliability and performance of the power system. Proper integration helps maximize inductor capabilities, directly contributing to improved power quality and efficiency of electrical circuits.

The C0402C103J3RACTU capacitor from SACOH is an exemplary component designed to facilitate efficient data transfer and promote environmental friendliness. Its sustainable characteristics make it a preferred choice for power quality solutions. The capacitor's compact size, combined with high reliability, renders it ideal for integration into modern electronic devices where space and performance are paramount. Additionally, this component excels in reducing noise and stabilizing power supply in high-frequency applications, ensuring optimal performance.

The H5TC4G63EFR-RDA integrated circuit from SACOH stands out for its high scalability and robust performance, making it particularly suitable for complex power systems. Its advanced design supports a broad application range, from industrial automation to consumer electronics, which ensures versatility and reliability across diverse sectors. Notably, this component excels in managing power distribution and enhancing overall system efficiency, crucial for modern electronic solutions requiring balancing power loads efficiently.

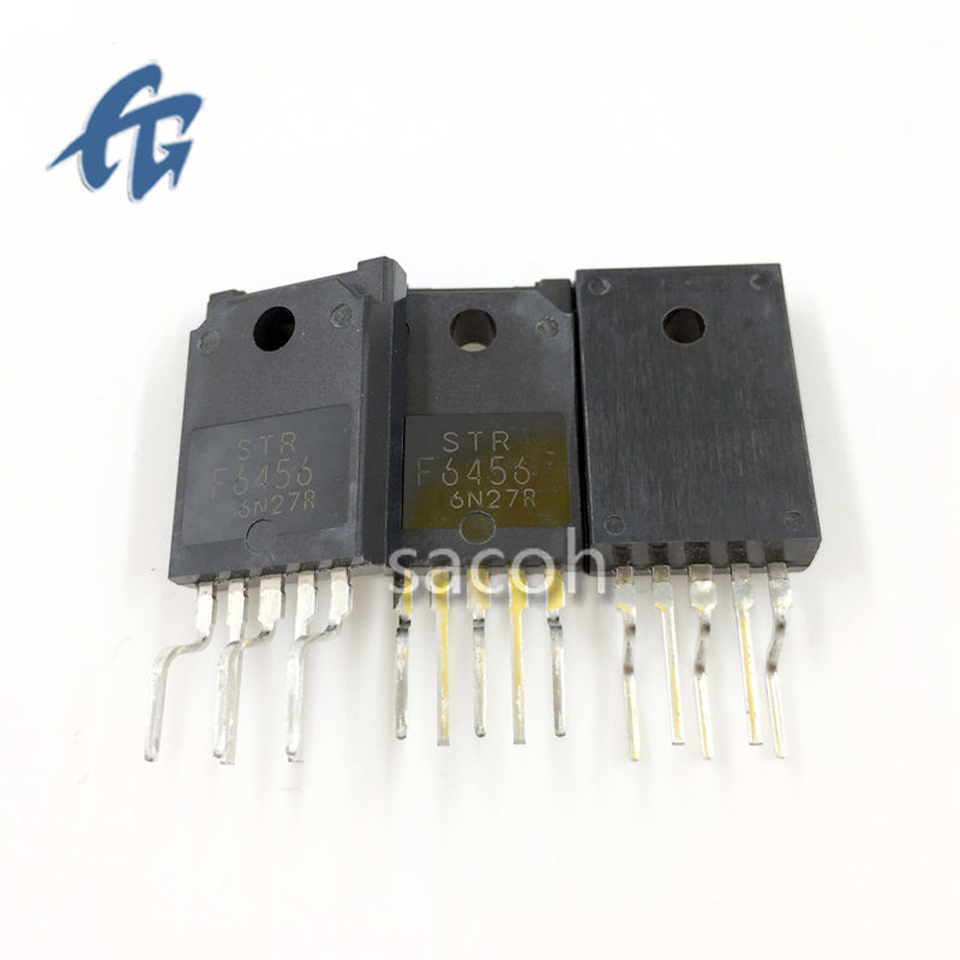

The STRF6456 microcontroller from SACOH utilizes smart chip technology to significantly enhance power quality and system performance. Among its advanced features are real-time monitoring and adaptive control, which collectively optimize power usage and minimize energy waste. This microcontroller is ideal for applications requiring precise power management and high reliability, such as renewable energy systems and smart grids, providing a future-focused solution for power management challenges.

Inductors play a crucial role in smart grids, which rely on advanced inductor technology to efficiently manage power flow, minimize losses, and integrate renewable energy sources. In smart grids, inductors help stabilize voltage and current, thereby ensuring a reliable and efficient power supply to consumers. As these grids continue to evolve, the role of inductors will become even more significant, especially in enabling real-time monitoring and adaptive control of power systems. This evolution not only enhances power quality but also supports the integration of renewable energy, paving the way for a more sustainable energy ecosystem.

Recent advancements in inductor design are focused on improving efficiency, reducing size, and enhancing thermal performance. Innovations such as 3D-printed inductors and the use of nanomaterials are setting the stage for more compact and powerful components. These cutting-edge developments are expected to drive the adoption of inductors in next-generation power systems, including electric vehicles and IoT devices. The integration of such innovative designs can lead to significant performance gains, reduced energy consumption, and improved reliability in various applications, ultimately contributing to a sustainable future in power management technology.